This project in Utah came with many challenges. As with any project, there are unforeseen obstacles that challenge your abilities as a project manager. This was one of those projects.

The project called for the removal of four vessels of unknown weight that were filled with Asbestos. Project manager Brett Krage, in all spent over two years making sure this project was safely finished.

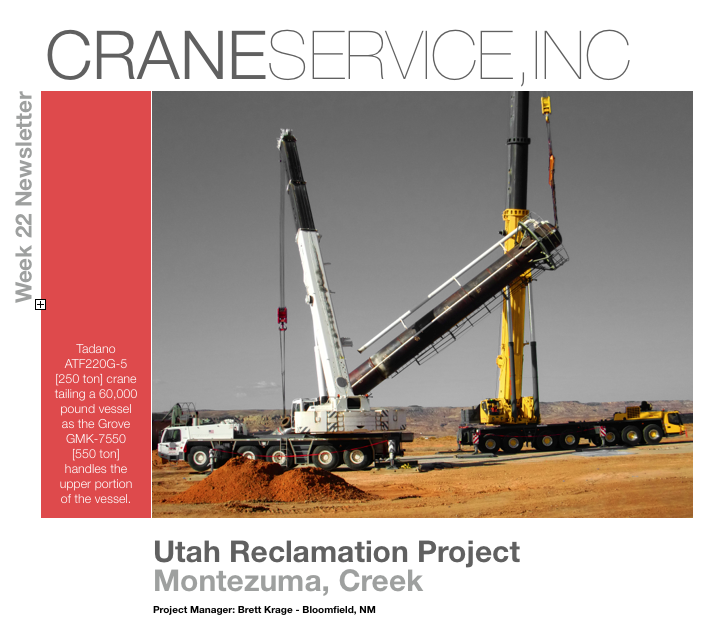

The process was not easy. Brett sourced engineers to design specialized lifting lugs for the vessels. After they were produced our master welder, Brandon Lansford, fused the lugs to the vessels with a 1 inch weld. Once the welds were certified we were able to start the process of getting the site prepped for the lifts. This involved revisiting the 3D Lift plan’s and discussing step-by-step how we were going to safely hoist the vessels to the ground with the site staff.

The project was completed perfectly and on-time.

Vessel Specifications:

- Tower 1 77 feet tall – 60,000 lbs

- Tower 2 76 feet tall – 160,000 lbs

- Tower 3 66 feet tall – 162,000 lbs